When best-in-class automotive manufacturing meets best-in-class medical device expertise, you get Trident.

The result is simple: lower cost, higher quality devices—delivered to market faster.

Contact Us

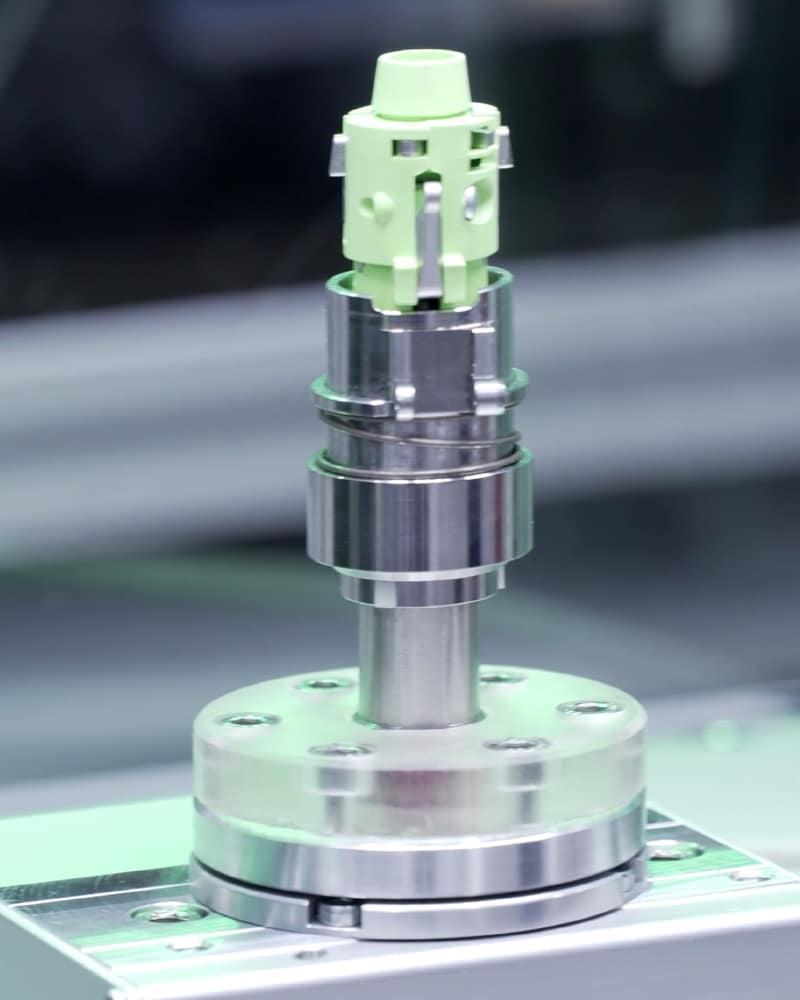

Built Different by Design

Trident’s approach was shaped outside the medical device industry. Our founder spent 30 years leading a best-in-class automotive injection molding business, producing safety-critical components under zero-defect standards. When the 2009 downturn halted auto production, that manufacturing discipline was intentionally brought into medical device development and production.

What That Means For You

Trident applies proven automotive manufacturing rigor to medical devices:

•

Lean, waste-elimination systems

•

Design-for-manufacturability from day one

•

Disciplined, repeatable processes

•

A zero-defect quality mindset

This is how innovation, compliance, quality, and cost efficiency work together—not against each other.

True End-to-End Execution

From early-stage development through validation, manufacturing, and sterile packaging, Trident delivers finished, ready-to-ship medical devices.

We manage:

•

All components and supplier relationships

•

Complex, multi-part assemblies

•

Validation and compliance support

•

Final packaging and delivery

You place one order. You receive the fully packaged device.

Why It Works

•

Fewer handoffs

•

Reduced Risk

•

Faster time to market

•

Lower total cost

•

Exceptional quality at ever step

Complex devices. Simplified. Done right.

Flawless Compliance

We know because at Trident, we live by these truths. Our company is built on the strength of our success in OEM Automotive manufacturing and our absolute commitment to quality, compliance and standards demanded by the medical field. We offer the best of both worlds. Exceptional quality, flawless Compliance and a hyper focus on driving waste from the process to improve cost, manufacturability and quality.

Let's discuss your manufacturing needs

Contact Us