WE ARE 100% DEDICATED TO THE DESIGN, DEVELOPMENT & MANUFACTURING OF MEDICAL DEVICES

Whether you need help on a concept or you have a finished design

At Trident Manufacturing, we live by the mantra “build it better for less.” We use our ingenuity and manufacturing expertise to look at all phases of the process (design, manufacturing, cost, and quality), thus driving excess waste out to ensure our customers receive innovative designs, flawless product launches and world class quality at a globally competitive price.

Let's Discuss Your Device

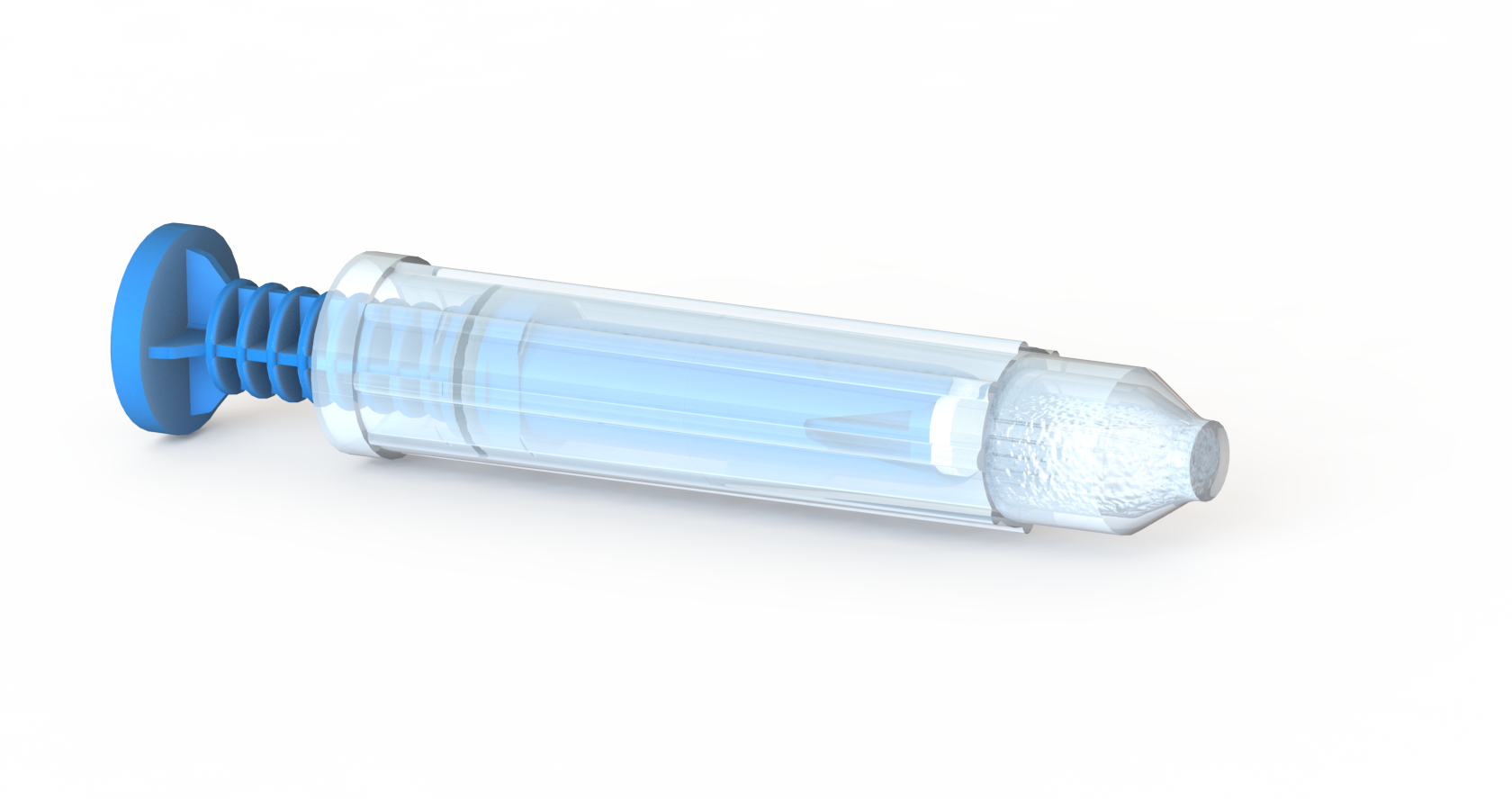

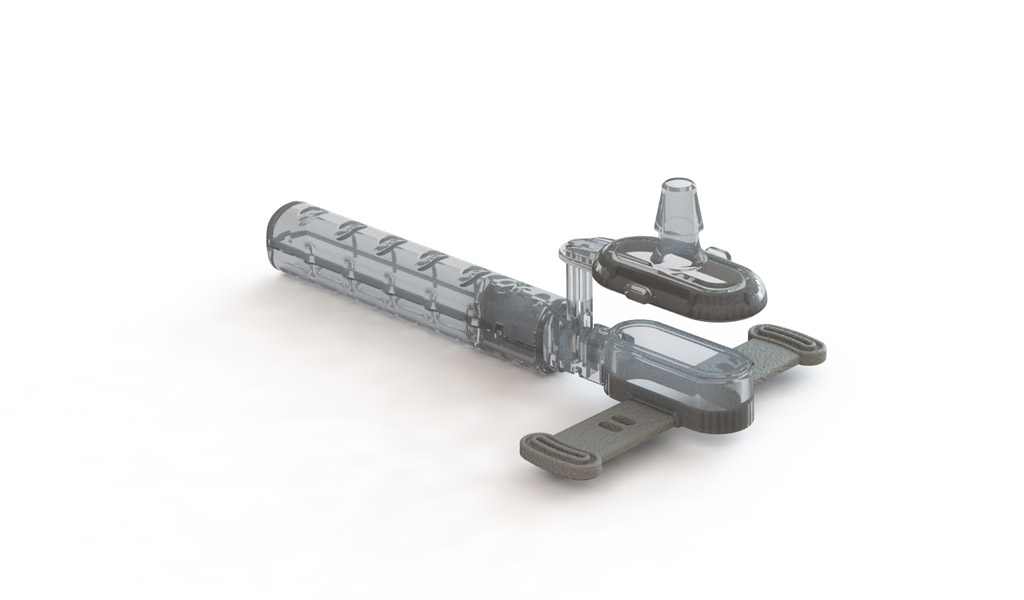

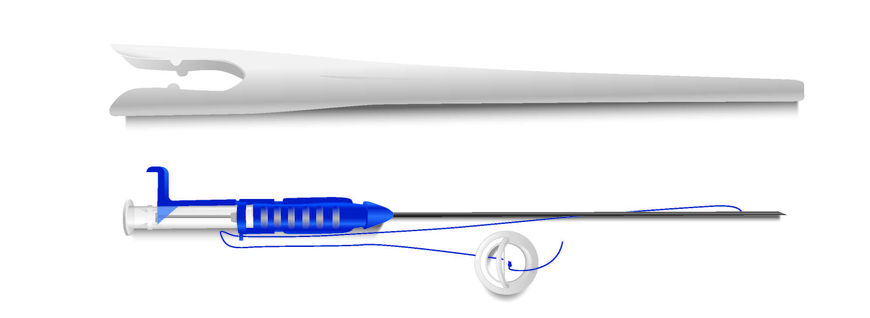

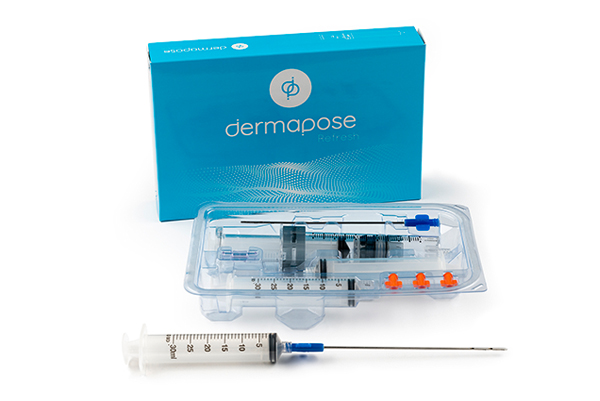

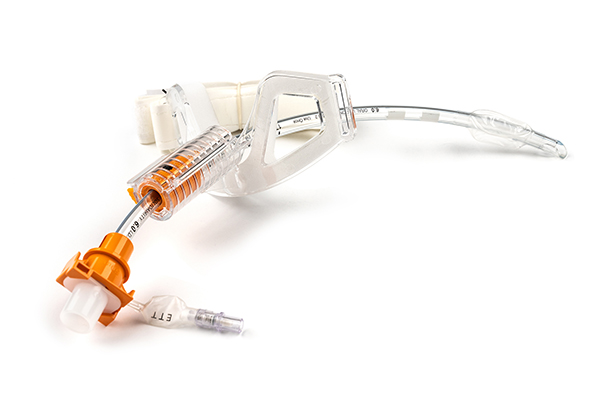

Examples of Trident Manufactured Products

We don’t let convention and habit get in the way of effective engineering

We use the best of traditional and non-traditional approaches to solve customers technical problems. This results in innovative products, efficient manufacturing and insightful planning which automatically leads to successful devices.

“The Engineering staff ensures ultimate optimization of processes with attention to every technical detail.”

John Sapiente - CEO Trident Manufacturing

We will work with you to ensure complete program success. Whether it’s Part Design, Assembly Development, Mold Design, Fixture Design, Manufacturing Analysis, Value Added and Secondary Operations or Prototyping, we are a full solutions manufacturer for medical devices