Trident’s manufacturing ability to provide an uninterrupted supply of product that meets our customers’ exact specifications is the result of years of experience and continuous learning.

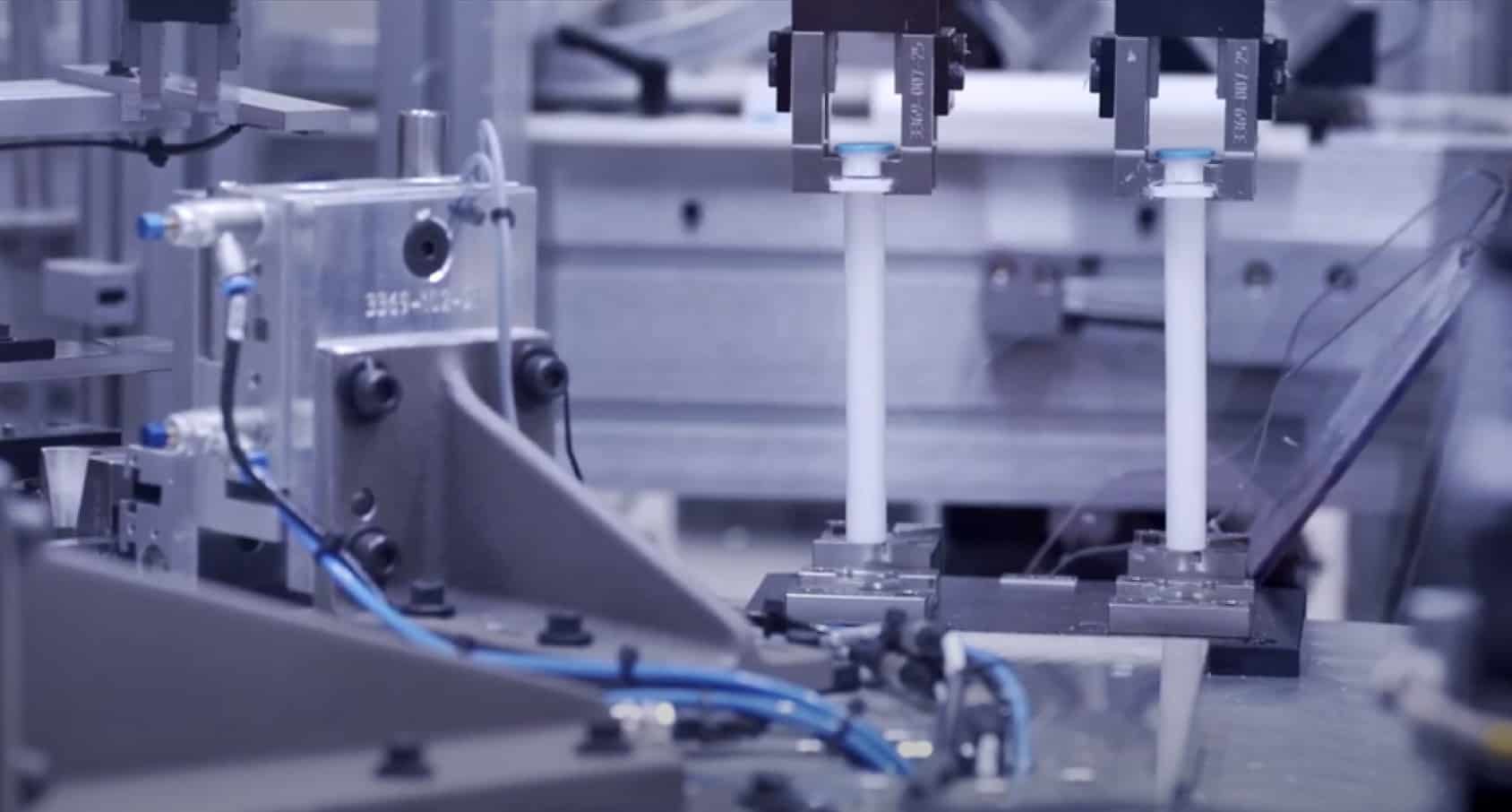

Trident Manufacturing employs Lean Automotive principles and best-in-class medical device compliance throughout our operations and the life cycle of your product.

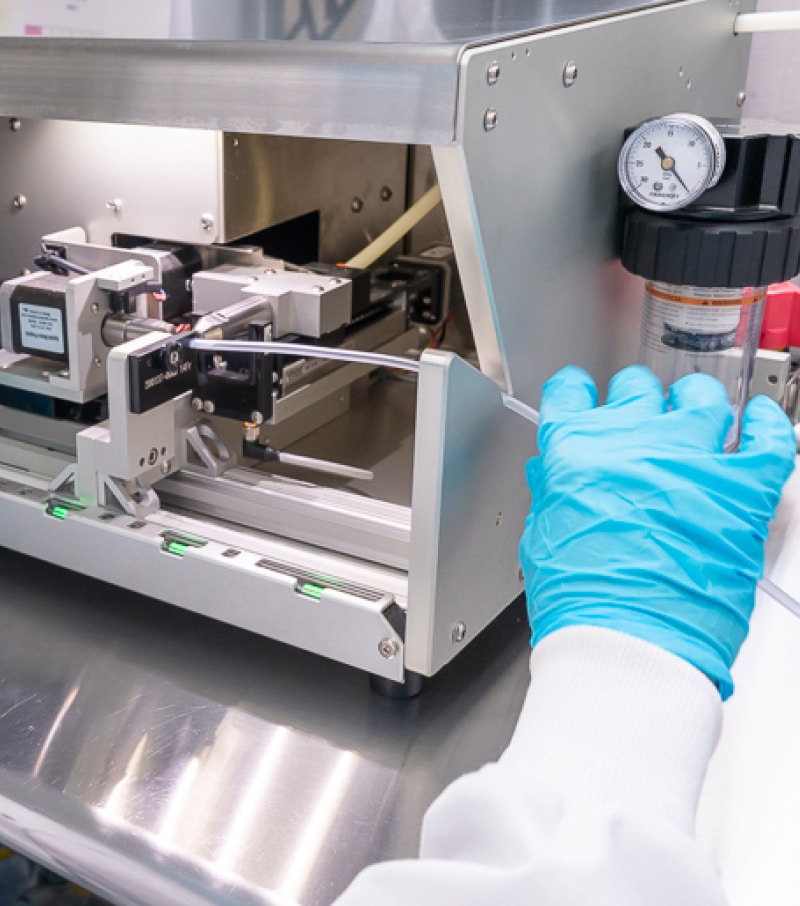

Trident Manufacturing medical device manufacturing services include FDA registered production, assembly and packaging capabilities with class 7 clean room capabilities. Our advanced process controls, expertise in lean manufacturing, and automation systems make it possible for Trident Manufacturing to partner with our customers to deliver exceptional quality while still providing a globally competitive price.

We’re Trident, your turnkey manufacturing resource for sterile or non-sterile class 1 and class 2 medical devices (mechanical or electro-mechanical):

•

Product Design

•

Engineering Medical Device Design Optimization and DFM

•

Rapid Prototyping and 3D Printing

•

Design and Production Validation

•

Component Manufacturing

•

Strategic Supply Chain Management

•

Class 7 Cleanroom or General Assembly

•

Contract Manufacturing Complete Packaged Device

- Plastic Welding (Ultrasonic, Vibration and Heat Staking)

- Gluing

- Electronics

- Suture Management

- Needle and Catheter Assembly

- Podding

- Welding

- Crimping

- Catheter Tipping, Drilling and Printing

- Tube Sets and Solvent Bonding

- Pad Printing

- Laser Marking

- Filtration, Foam and Media

•

Testing

•

Device, Multi-Pack and Master Carton Packaging with UDI Serialized Capabilities

•

Sterilization Management

•

ISO 13485 Certified, Med Accred and FDA Registered

Let's discuss your manufacturing needs

Contact Us